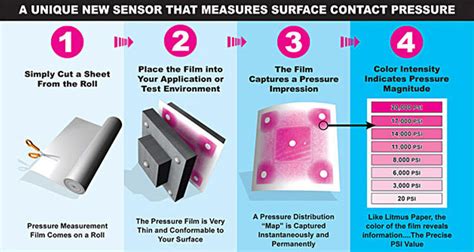

pressure film impact testing|prescale film specs : wholesale Fujifilm developed Prescale ® to reveal pressure between any two contacting surfaces. This thin flexible film conforms to both straight and curved surfaces .

Resultado da Zona 7, Maringá - PR 36 anos • Documentos verificados Para criar um anúncio no Fatal Model, o(a) anunciante deve cadastrar seu documento .

{plog:ftitle_list}

WEBLibreflix é uma plataforma de streaming aberta e colaborativa que reúne produções audiovisuais independentes, de livre exibição e que fazem pensar.

Prescale allows you to easily measure pressure distribution and range. Created using Fujifilm's advanced thin film coating technologies, the pressure inspection sensor on the entirety of the film allows you to confirm pressure distribution of the entire surface at a glance.Pressure Image Analysis App. FUJIFILM Prescale Mobile. The app that enables .Prescale is designed to have pressure applied to the film from directly above. .Fujifilm Prescale ® is a unique, affordable and easy to use tool that reveals the distribution and magnitude of pressure between any two contacting, mating or impacting surfaces. Pressure indicating sensor film is extremely thin (4 to 8 .

Identify pressure distribution between gear teeth. Fujifilm's Prescale Film is a single-use, pressure sensitive film that measures pressure ranging from 0.05 to 300 Mpa (about 7 to 43,500 psi) through peak pressure snapshots.Fujifilm developed Prescale ® to reveal pressure between any two contacting surfaces. This thin flexible film conforms to both straight and curved surfaces .Our pressure sensitive film is a highly accurate, affordable and easy to use sensor that reveals the distribution and magnitude of pressure between any two contacting, mating or impacting .Our Impact Force Measurement Kit allows technicians to measure pressure distribution and magnitude between any two contacting or impacting surfaces. The actual pressure test is quite quick requiring less than 5 minutes.

Pressure Image Analysis App. FUJIFILM Prescale Mobile. The app that enables any user to quantify pressure and other analysis results with ease.

Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, aerospace, and construction to guarantee . If it is determined that the sealing pressure revealed by the Fuji film is not acceptable, CGR Products can use the film data to determine a possible revised gasket design. These tests can also reveal that a material . An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .Hydrostatic testing is one of the most widely used methods for evaluating the structural integrity of pressure vessels. During this process, the vessel is completely filled with liquid, typically water, and pressurized to a level that .

slap.tear test

Large Missile Level D Impact & Cyclic Pressure Load Testing. Watch this video to see what happens to a window during a hurricane. You will see how the forces of nature will pull and push the window in and out of a wall opening. The cyclic .

Hydrostatic pressure testing is a method used to test pressure vessels for strength and leak-tightness. These vessels include pipelines, gas cylinders, fire extinguishers, etc. It consists of filling a vessel with a certain amount of water or some other incompressible fluid and pressuring it above the intended operating pressure before .The sequence of testing for products that must meet the water requirements of protocol TAS202 is first, test the air infiltration. Second, load the product to 0.5 x test load. Third, load to design pressure. Fourth, test the water at its corresponding pressure. Lastly, test to full test load. An impact test is used to determine a material’s impact strength, or the material’s ability to resist deformation when subjected to a sudden shock or impulse load. . The manufacturing of some parts that require a specific level of toughness, such as ship hull components or pressure vessels, benefits greatly from impact testing. Impact . Pressure Metrics LLC. 531 US Highway 22E. Suite 323 . Whitehouse Station, NJ 08889. Call us now: +1 866-963-2392 Email: [email protected]

How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .

This is the pressure sensitive film.Pressure and pressure distribution, . Research Tools & QC Testing. Life Sciences. Graphic Arts & Printing. Photofinishing & Personalized Photo Products. . There is an example of The peak impact pressure and its distribution of a ball of softball. View the table of contents.Figure 2: Results from a packaging drop test displays pressure distribution in finite detail. #3 - Impact Force from Packaging Drop Test. Knowledge of how a product will react in different drop testing scenarios can help manufacturers determine the best way to pack a product for shipping, and what could happen if the end user were to drop the .Bryan, C. "NASA Mechanical Impact Testing in High-Pressure Oxygen." Flammability and Sensitivity of Materials in Oxygen-Enriched Atmospheres. Ed. Werley, B. 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959: ASTM International, 1983.

While it is important to note that impact-resistant glass may still break, the goal of this test is to ensure that the window remains intact and stays within its frame upon impact. Large Missile Impact Testing: For large missile impact testing, a significant piece of lumber (a 9-pound, 2×4) travels at a speed of 50 feet per second and is . Fujifilm Prescale Low Pressure (LW) – Surface Pressure Mapping - Pressure Indicating Film - Tactile Sensor - Pressure Range 350-1,400 PSI; 32.8 ft. x 10.6 in. Film Roll Fujifilm Prescale Extreme Low LLLLW (4LW) - Surface Pressure Mapping; Pressure Indicating Film; Tactile Sensor - Pressure Range 7.2-28 PSI; 3 ft. x 12.6 in. Section

Prescale Pressure Measurement Film measures pressure and pressure distribution. Nine models of Prescale cover a wide range of applications from extremely low to super-high pressures with easy operation from 0.006 MPa to 300MPa. . Heat sealing (Packaging) Impact Pressure. B: Function testing of golf C: Pressure on freight during transportation .5.1 Test specimen - All parts of the test specimen shall be full size, using the same materials, details, methods of construction and methods of attachment as proposed for actual use. The specimen shall consist of the entire assembled unit attached to a given type of structural framing of the building, and shall contain all devices used to resist wind forces and windborne debris.

Testing pressure-sensitive adhesives under standard conditions of temperature and relative humidity is always a preferred means to compare data from lab to lab and from lot to lot. However, there are times when it is .Impact testing is used to measure an objects, material, or coatings ability to resist high-rate loading, normally thought of as two objects colliding at high relative speed. A coating's ability to resist impact is one of the major .In essence, the Charpy impact test is primarily used on metals while the Izod impact test can be used on both metals and plastics. So, if you are in search of a plastic impact tester, you should go for Izod. Many industries use Izod impact .

The evaporation rate from a meniscus is controlled by a competition between a high superheat at the liquid–vapor interface and a suppressed liquid pressure due to the effects of the capillary pressure (P c) and/or the disjoining pressure (P d).P c depends on the meniscus curvature and decreases as the meniscus becomes flatter. P d was first proposed by .The ability to measure surface pressures and pressure distributions with the unique Fuji pressure sensitive film has been available for more than 30 years. . – Impact pressure on fracture testing of packaging – Medical applications for the determination of footprints, or pressure distributions on the seat in wheelchairs . The Taylor impact test (also referred to as the rod impact test) consists in firing, via a powder or gas driven gun, a mm- to cm-sized cylinder, having an aspect ratio L/D of > 5, up to a few kilometers per second toward a massive, non-deformable (highly rigid) target. 19 Because the projectile and not the target is the sample of interest .

Request PDF | Impact damage to apple fruits in commercial corrugated fiberboard box packaging evaluated by the pressure-sensitive film technique | During transport and handling, apple fruits . Upon impact, the pressure in the glass film builds up by 2–3 reverberations through its thickness. The time on the normal signal at which the local dip is observed corresponds to the first ring-up in the glass film, building up an initial pressure of ~ 5GPa. . Mechanical testing of ceramics and ceramic composites, AMD, vol 197. ASME, New .

ASME B31.3 INTERPRETATIONS Interpretation 25-02 Subject: Para. 302.3.5(c), Stress Due to Sustained Loads (B31.3-2012) Date Issued: April 14, 2014Following the tests, the Pressure Film sheets were sent to Sensor Products for optical imaging and analysis using the Topaq ® Pressure Analysis System. Topaq ® revealed the areas of highest impact pressure as transmitted through the samples tested. A pseudo-coloring of the scanned 2D and 3D image showed, in the yellow-orange area, where the values of the impact .

Pressure sensitive film can measure surface pressure distribution whether it is used as an impact force sensor, seat pressure sensor, as a strain gauge or even as nip impression paper. Fujifilm Prescale ® is a Mylar-based film that contains a layer of tiny microcapsules. Force exerted on this pressure sensitive film causes the microcapsules to .

sm tube tear test

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test machine is released to strike a notched specimen, and the amount of energy absorbed during the break is calculated.III. Key Requirements of ASME B31 3 for Pipe Pressure Testing A. Pressure Limits and Testing Criteria. ASME B31.3 sets specific pressure limits and testing criteria for process piping. The standard outlines the maximum allowable pressure and temperature ratings, considering material properties, design conditions, and safety factors.

pressure measuring film

Resultado da Brida Nunes (@bridanunesreal) no TikTok |906.8K curtidas.157.2K seguidores.Insta: bridanunesprivado Me segue lá 👆.Assista ao último vídeo .

pressure film impact testing|prescale film specs